Silicon and germanium are two essential elements that have revolutionized our daily lives through their diverse applications. Both these elements play vital roles in various scientific, industrial, and technological domains. In this comprehensive blog post, we will delve deeper into the fundamental needs for silicon and germanium, examine the environmental implications of their production, and explore how innovative techniques like custom crystal growth are paving the way for sustainable development and a greener future.

Understanding the Needs for Silicon and Germanium:

1. Silicon:

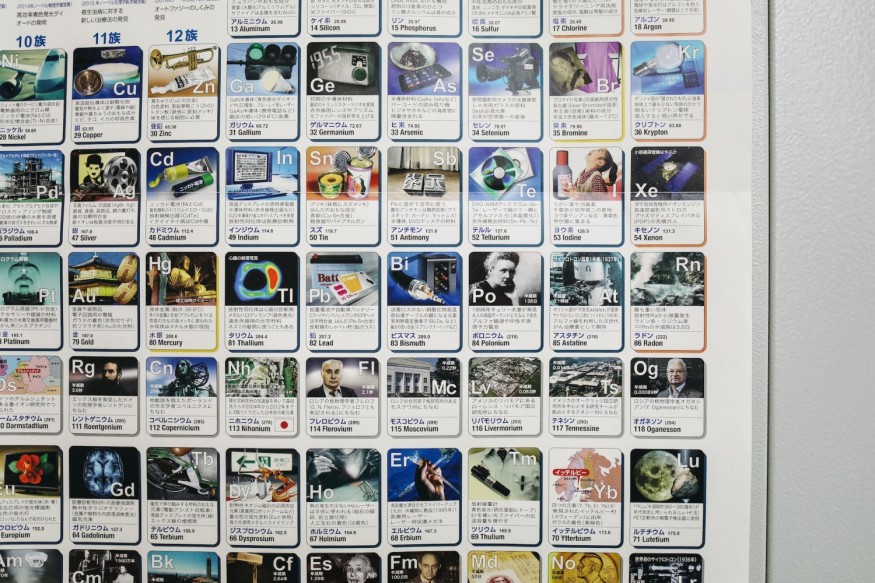

Silicon, the second most abundant element in the Earth's crust, is a fundamental material in modern technology. Its exceptional semiconducting properties are the backbone of electronics, enabling the creation of microchips, transistors, and integrated circuits. Silicon's ability to form strong and flexible bonds with other elements contributes to its versatility in various industries, including construction, medical devices, and automotive applications.

Silicon's significance in renewable energy cannot be overstated. Solar panels, which harness sunlight and convert it into electricity, rely on high-purity silicon to achieve optimal efficiency. The integration of silicon in photovoltaic cells has played a pivotal role in driving the adoption of solar energy as a cleaner and renewable alternative to fossil fuels.

2. Germanium:

Germanium, a less-known element, is vital for its use in optical fibers, infrared technologies, and as an alloying agent in specific metals. It possesses unique properties that enhance the performance of materials in critical applications, such as high-performance lenses, telecommunications, and space exploration.

Germanium's high refractive index and low dispersion properties make it ideal for the manufacturing of optical lenses, providing exceptional clarity and focus. Infrared technologies that utilize germanium are essential for night vision devices, thermal imaging cameras, and missile guidance systems, enhancing military and security applications.

Environmental Impact of Developing Silicon and Germanium:

1. Energy Consumption:

The production of silicon and germanium typically involves energy-intensive processes. Extracting pure silicon from silica requires significant amounts of electricity, while germanium extraction is closely linked with zinc refining and poses challenges in terms of energy consumption and waste generation.

However, advancements in energy-efficient technologies and the increasing use of renewable energy sources are helping to mitigate the environmental impact of these processes. Solar energy, for example, is not only harnessed by silicon-based solar panels but is also used in the production of silicon itself, making the manufacturing process more sustainable.

2. Greenhouse Gas Emissions:

The high temperatures needed to process silicon and germanium lead to substantial greenhouse gas emissions, primarily in the form of carbon dioxide. Additionally, the mining and refining processes contribute to air and water pollution, impacting local ecosystems and human health.

Governments and industries are increasingly adopting cleaner production methods and stricter environmental regulations to reduce emissions and minimize the impact of silicon and germanium production. Furthermore, research is underway to develop more environmentally friendly extraction and refining techniques, including processes that capture and repurpose carbon emissions.

3. Resource Depletion:

Silicon and germanium extraction can put stress on natural resources. While silicon is abundant in nature, the demand for high-purity silicon for electronics and solar panels can deplete specific high-grade sources. Germanium, being rarer, requires careful extraction and responsible resource management.

Recycling and reusing silicon-based products have gained traction to alleviate the strain on natural resources. Initiatives are being taken to recover silicon and other valuable elements from electronic waste, reducing the need for raw material extraction and contributing to the circular economy.

Innovations in Custom Crystal Growth:

1. Custom Crystal Growth Techniques:

Custom crystal growth involves carefully controlled processes to produce high-quality, large, and pure crystals. This technique enables the creation of tailor-made materials with enhanced properties, reducing the need for excessive resource consumption and waste generation.

The process of custom crystal growth involves manipulating crystal lattice structures, impurity levels, and crystal orientation to obtain materials with specific properties. For instance, custom crystal growth has been instrumental in producing silicon wafers with minimal defect densities, improving the efficiency and reliability of electronic devices.

2. Advantages of Custom Crystal Growth:

By using custom crystal growth, scientists and engineers can design materials with specific characteristics, reducing the reliance on naturally occurring, finite resources. This innovation contributes to more sustainable production methods and minimizes the environmental impact associated with silicon and germanium extraction.

Custom crystal growth techniques also allow for the synthesis of materials that are more durable, efficient, and environmentally friendly. For instance, the production of high-quality germanium crystals has led to significant advancements in infrared sensors, enabling safer and more accurate detection systems.

3. Wider Applications:

Custom crystal growth techniques are not limited to silicon and germanium. They are also being employed in the development of other critical materials, such as gallium nitride for efficient LEDs and high-power devices, and sapphire for robust optical components.

By expanding the scope of custom crystal growth to other elements and compounds, researchers are paving the way for a new era of sustainable materials. These innovations have the potential to revolutionize various industries and drive progress towards a more sustainable and eco-friendly future.

Silicon and germanium are indispensable elements that underpin various technological advancements, making them essential for our modern world. However, their development has significant environmental implications, from energy consumption and greenhouse gas emissions to resource depletion.

Custom crystal growth offers a promising solution to mitigate these environmental impacts by providing a more sustainable approach to material production. Embracing innovations like custom crystal growth can help us unlock the full potential of silicon, germanium, and other materials while preserving our planet for future generations.

As science and technology continue to evolve, responsible and sustainable practices must be at the forefront of our journey into the future. With concerted efforts, we can harness the power of silicon and germanium while minimizing their impact on the environment and fostering a greener and more prosperous world for generations to come.

© 2026 NatureWorldNews.com All rights reserved. Do not reproduce without permission.